Precious metals represent a key facet of the hydrogen society to come. Platinum-based catalysts, for example, are essential to building fuel cells — a core hydrogen technology. Tokyo-based Tanaka Precious Metal Technologies Co. has been developing fuel cell catalysts since the 1980s and is a global player in the drive to make the planet more sustainable by utilizing the unique properties of platinum and other precious metals.

Platinum-grade foresight

Founded 139 years ago during the Meiji Era (1868 to 1912), Tanaka was originally a money exchange. It then began dealing in platinum, later becoming the first in Japan to succeed in manufacturing catalytic platinum mesh. Today, Tanaka stands as a leader in precious metal products with three primary business pillars: advanced materials for industrial use, asset products such as bullion and coins, and jewelry.

Tanaka’s branches and affiliates cover countries and territories ranging from the United States and Germany to Asia, including Singapore, Malaysia, Thailand, China, South Korea and Taiwan. The company offers total solutions for bullion procurement as well as development and manufacturing, sales and recycling through its advanced technologies and international network.

A dedicated development department set up about 30 years ago led to Tanaka launching its FC Catalyst Development Center in 2013 to set up a mass production framework. In 2018, the growing call for a true hydrogen society spurred Tanaka to expand production. Next on the agenda is overseas production bases, with fuel cell electrode catalyst production due to begin in China in 2026 for the Chinese market.

“We started out making materials for catalysts, and then moved on to developing combustion catalysts and fuel cell catalysts ourselves,” said Tanaka’s Chief Operating Officer Tomoyuki Tada, who’s been focused on fuel cell development and hydrogen since the early days.

“Investing in the hydrogen field was at that time an adventure, but we anticipated the arrival of the hydrogen society.”

Around the same time, Tada noted, Tanaka’s science and technology team dove into finding ways to use precious metals in cancer drugs and other pharmaceuticals. Fueled by the ambition of one day becoming a catalyst manufacturer that could “contribute something to people’s health and lives,” the company took its first step on the long journey to materials development for a hydrogen society.

Core tech with clean output

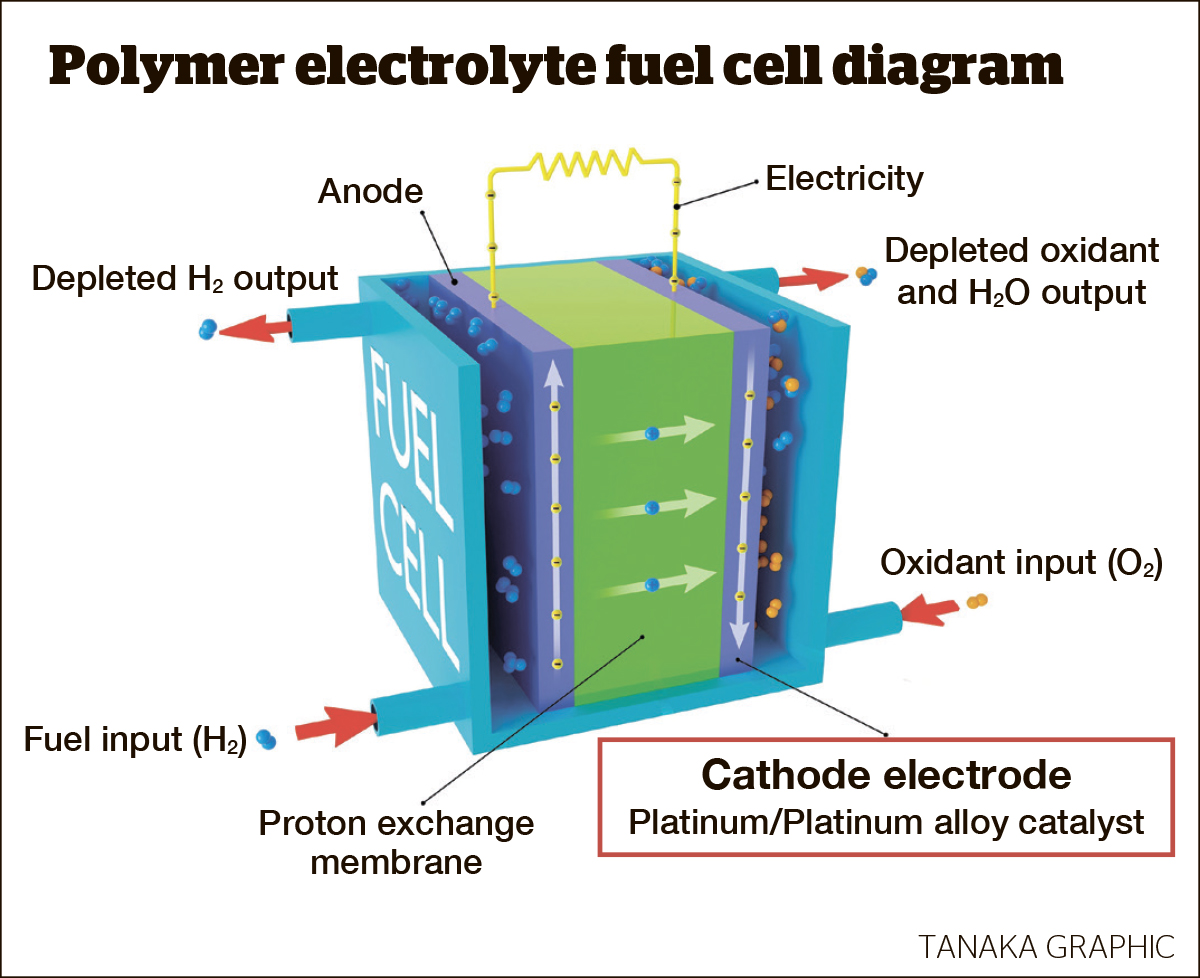

Fuel cells — formally known as polymer electrolyte fuel cells — emit only water as a byproduct, meaning their output of carbon dioxide and other pollutants is zero.

Platinum-based catalysts are crucial to PEFC performance.

“A catalyst is something that facilitates change without changing itself,” Tada explained. “PEFCs need to react at low temperatures, and to make that reaction happen, we need a highly active catalyst like platinum. While other catalyst materials — including nonmetallic ones — are being researched, their performance pales compared to that of platinum.”

What turned Tanaka into Japan’s undisputed leader in fuel cell catalysts is its platinum-ruthenium catalyst for Japanese Ene-Farm home-use fuel cells.

“This was the turning point that led to us dominating the Japanese market,” Tada said. “If we had not developed this catalyst, Ene-Farm might not have been realized. It was also the trigger that gave us the confidence to expand overseas.”

Tada explained that while all companies use platinum and carbon for fuel cell catalysts, Tanaka has a key advantage: a sophisticated technology that evenly disperses platinum onto carbon.

Ahead of the game

Although other companies are catching up with Tanaka’s dispersion technology, the company has the added strength of being a pioneer.

“Customers process our catalyst, which is a nanoscale powder, into layers,” Tada said. “Since we were one step ahead in making and selling quality catalysts, their processing ‘recipes’ are tailored to the properties of our products so it would be difficult to switch to other suppliers.”

The company has succeeded in advancing its technology by connecting with global developers and openly sharing its expertise — a process now known as “open innovation.” Tanaka has openly provided its know-how to customers as well.

“I went to clients’ offices and showed them how to process the catalyst with a proper recipe so that they can experience the expected performance of the product,” Tada said. By supporting customers with product development, Tanaka was able to deepen communication, receive feedback and apply that knowledge to the improvement of its own products.

Hydrogen society trials

Sourcing hydrogen and addressing its sustainability and high costs are thorny challenges in achieving a hydrogen society, he said.

“Hydrogen is a secondary energy source,” Tada said, “and unlike fossil fuels such as oil, it needs to be made from something. And producing hydrogen using natural gas or fossil fuels as fuel, or by electrolyzing water, requires huge amounts of money and time. So does procuring hydrogen from overseas. The infrastructure, such as hydrogen stations and supplying hydrogen to them, is not there yet either.”

One issue is how to switch from “gray” hydrogen — which is derived from carbon dioxide-emitting fossil fuels — to “green” hydrogen, which is derived from renewable energy sources.

Polymer electrolyte membrane water electrolysis (PEMWE) is the simplest solution, but also one of the most expensive.

“We’re also developing electrode catalysts for PEMWE,” Tada explained. “But the process uses a precious metal called iridium, which is a limited resource and costs about ¥20,000 per gram, so we need to consider how to use it effectively.”

Tanaka is installing a 500-kilowatt fuel cell system at its main precious metal recycling business site in Shonan, Kanagawa Prefecture, to help demonstrate the potential of hydrogen energy. Scheduled to go online in 2026, the fuel cell system will be one of the largest private-use systems of its kind in Japan and generate 25% of the electricity used at the plant.

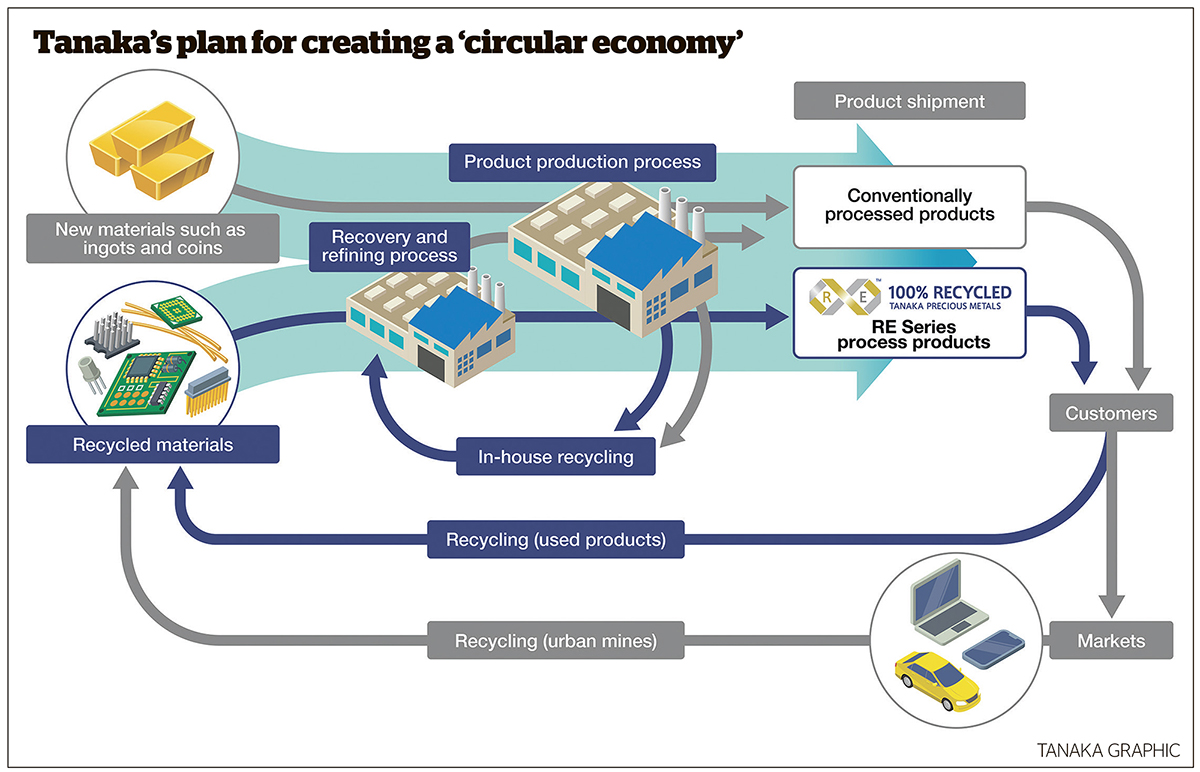

Since precious metals are scarce, recycling has long been a part of Tanaka’s DNA. The company is determined to create a resource circulation system that covers all stages from procurement and manufacturing to sales and recycling. To ensure its supply of the metals, Tanaka also plans to deepen its procurement relationships with mines.

Beyond that, Tanaka collects these metals from scrap, second-hand products and equipment and recycles them at its own plants. It also works incessantly to improve performance, durability and dispersion to reduce platinum usage and costs.

Mining for the future

When it comes to materials development and research, Tanaka keeps its eyes focused on the horizon and avoids the temptation of jumping onto industry trends and fads.

“We don’t let big stories from others sway us,” Tada said. “We support the market’s growth in a strategic, long-term manner, with a calm perspective. We can do this because we’re a market leader that can see the entire market. We also have a strong will to continue until the hydrogen society is realized.”

“We fully understand that attainment of a hydrogen society is not easy,” Tada said. “Even if the achievement of our goal takes another 10, 20 or even 30 years, we are resolved, determined and willing to invest as much time as is necessary in research and development.”

This article is sponsored by Tanaka Precious Metal Technologies Co. (https://tanaka-preciousmetals.com/en/)