Rix is a manufacturing and trading company headquartered in the city of Fukuoka, with about 40 branches and 10 subsidiaries in Japan and 12 subsidiaries overseas. In a recent interview with The Japan Times, three Rix executives spoke about the company’s strengths, areas of specialization and efforts to collaborate with other manufacturers to explore new potential in the industry.

“The company started in 1907 as a distributor of tabi (Japanese split-toe socks), so we have a long history of working with the industrial sector. Through their daily communication with customers, the workers learned what their customers’ problems and needs were, and started looking for products and solutions, which was the beginning of our history as a trading company,” said Representative Director, President and Executive Officer Takashi Yasui.

The company’s lines of business expanded as it sought suppliers in Japan and abroad and asked manufacturers to produce new items based on its customers’ needs. “In our current trading section, we have about 3,000 items, mostly industrial products and parts such as pumps, valves, seals and filters from more than 3,000 suppliers,” Yasui said.

In 1967, Rix began manufacturing high-pressure hydraulic pumps, the result of its commitment to meeting customer needs. Since then, the company has gradually expanded its role as a manufacturer while maintaining its capability as a trading company.

“Our manufacturing division has three pillars: high-pressure hydraulic technology, precision cleaning technology and sealing technology. Among the devices and machines we manufacture is a flux cleaning system that we developed to clean the space between the substrate and the motherboard of a chip,” said Fluid Device Engineering Department Manager Hiroyuki Okamoto.

On the other hand, chiplet technology is becoming mainstream in the semiconductor industry, creating a new demand for cleaning. This technology involves multiple small chips being placed on an intermediate substrate called an interposer and fitted into a single package. These require more flux cleaning in narrow gaps than conventional chip mountings.

Okamoto explained that Rix is developing a new flux cleaning machine to clean these very narrow gaps based on its existing technology.

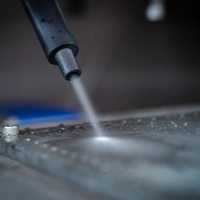

He also said that a micro-ice-jet precision cleaning nozzle developed by Rix is attracting attention from the semiconductor industry. When compressed air and water enter the nozzle, its special shape accelerates the water to supersonic speeds, causing adiabatic expansion that instantly turns the mix into ice particles so small they can clean chip wafers and semiconductor devices.

“Using this nozzle has been proven to strongly reduce nanoscale contamination on the surface of wafers. We are constantly updating the technology through joint research with semiconductor device manufacturers to improve performance while minimizing damage to the wafers by controlling the size and speed of the ice particles, so that the nozzle can be used to clean the most advanced wafers that must be handled with the utmost care and precision,” Okamoto said.

Rotary joints, one of Rix’s flagship products, are also used in semiconductor manufacturing, among other industries. Performance requirements vary by application, but cleanliness is the most important element in semiconductor production. “We have to make sure that the joints do not generate even microscopic dust when they rotate,” Okamoto said.

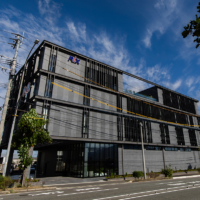

To expand its product line, Rix is seeking opportunities to collaborate with domestic and international manufacturers who possess unique technologies and has set up a new research lab just for that purpose. “To provide the space and equipment necessary for such collaborations, we opened a new research facility near Fukuoka Airport in November,” Yasui said. The facility called the Cooperative Creation Center includes a clean room.

“This is going to be a center for co-creation, and it plays the role of sowing the seeds for the future,” Yasui said.

Especially in semiconductors, where technology evolves at a rapid pace, it would be too slow to create an environment for research and development only when customer needs arise. Yasui said some of the company’s research projects are being carried out on a prospective basis, with no assurance that they will meet future customer needs, and highly valued this trend instead of showing concerns. “Our focus has long been on adding high value to our main products. So there weren’t many ideas that strayed from that focus. Now we have this place where new ideas are welcome,” Yasui said.

Kensaku Ida, manager of Electronics and Semiconductor Industry Professionals Promoting Department of the Global Sales Headquarters, said the company has already achieved a lot by introducing unique global products to Japan as a trading company and by meeting customer needs by manufacturing products using technologies the company excels in. Now it aims to invigorate the Japanese market by creating unique products of its own. To achieve this, it is not enough to simply install new equipment and use cutting-edge technologies at the center. “We want to establish partnerships with various suppliers and customers around the world to come up with new ideas,” Ida said.

At the same time, Rix’s strength as a trading company is growing. The range of products available in various fields, including semiconductors, is also expanding, and the company can now offer comprehensive solutions, such as repair and remanufacturing services, as well as products that are a combination of its own products and those of other companies.

Ida also said the goals behind procurement are changing on the customer side, especially in semiconductors. “Customers have always been concerned about how much cost reduction can be achieved through procurement,” he said. “But now there is demand for rare parts and parts that are no longer manufactured.”

In such cases, Rix can provide tailored support, made possible by the network of manufacturers and suppliers it has built up over the years. “For example, we have worked with manufacturers that have experience in other areas, such as the automotive industry, to handle items requested by our semiconductor customers,” he said.

Rix can also provide repair and maintenance services. “We used to outsource the repair work to manufacturers and partners, which is a typical role at a trading company, but now we work with them to repair and recycle various items such as pumps, power supplies and heaters, incorporating them into our own company as a manufacturer,” he said.

In fact, some of the items Rix repairs are products that were originally made by other manufacturers. Sometimes neither Rix nor other companies in Japan have the capability to repair a particular item. In such cases, Rix not only finds an overseas company that can repair the product, but a company that it can form a partnership with to bring the technology to Japan and handle domestic repair services, allowing it to provide timely support to customers.

The repair and recycling service is where Rix can take advantage of its close links with manufacturers and customers around the world as a trading company and its knowledge and experience as a manufacturer.

For overseas manufacturers and suppliers, Rix is a reliable partner with a wide variety of perspectives and capabilities, from sales and promotion to repair, recycling, research and development. It also boasts customers in a wide range of industries including steel, paper, semiconductors, machine tools, shipbuilding, automobiles, food, medicine and more. It already has accounts with many companies and their subsidiaries in Japan, helping to shorten what would otherwise be a long and tedious sales process.

“We can also suggest potential cross-industry cooperation among the companies we have connections with. And we know how and where to effectively promote new products,” he explained.

Yasui said he is looking forward to engaging multiple partners to not only serve its customers, but also stimulate the Japanese market.